It's not easy to create, it's not easy to craft your imagination out on a palette. But people who dedicate themselves and their lives for such are still alive. Oftentimes, when we come across crafts by ancient artisans and their progeny, we ponder over the fact astonishingly

‘Ki ye kaise banalete hain yaar’.

Well we consider them blessed with skills, but it's also their hard work and their addition to the already eccentric craft.

Kalamkari is no stranger to the people in India, and well actually all around the globe now. People are thriving to buy art everywhere, be it their entrancing block printed clothes, or hand painted bags, or decor. You name it, and the kalamkar does his magic on the very same. But do you want to dive deep into its story?

Kalakari ki ore Pehel

Not many people know about the origin of the Pedana Kalamkari. It started post-independence when Kamaladevi Chattopadhyay vowed to equally promote indigenous arts and crafts. She revived the textile and craft industry entirely. Her urge to delve deeper into the handicraft led her door to door to the village of machilipatnam, where she came across this ancient block printing technique. With the help of few funds, she then started a unit in Ballapuram, in 1949, but due to marketing issues it was shut down. But this did not kill the spirit of the other pedana people to popularize their impeccable ancient handicraft.

Pushton ki Kisht

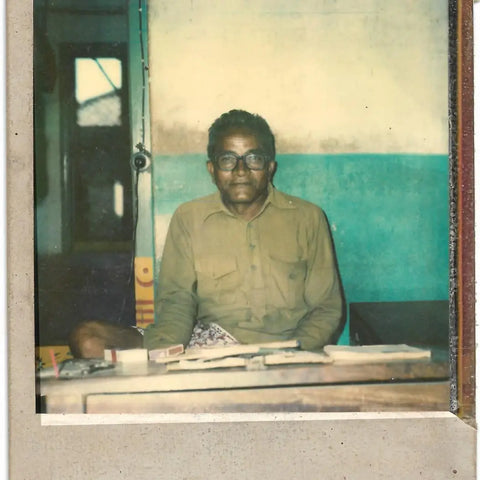

In 1970’s, while owning a fabric textile mill, Pitchuka Veera Subbaiah, father of Mr. Srinivas, used to visit different metropolitan cities with his fabric swatches. Whilst he was there, someone asked him to provide them with a kalamkari swatch, as it was a rare and unique kind of design. This idea led him to start his own mill in polavalani and pedana village.

We never realise how much our ancestors leave behind for us to cherish, learn and grow into. Sometimes when we are asked to get acquainted with it, we deviate ourselves from it calling it ‘outmoded’. But time has changed, and so has our youth. They are mesmerized by the craft and creativity, and hence, want to continue to breed it.

Something similar happened with Varun, an engineer by profession, whose father Mr. Pitchuka Srinivas, has been keeping the Pedana Kalamkari alive and is one of the artisans in the country who still follows the original technique of hand-block printed Kalamkari.

He dropped out of education in 1983 to continue his family work. Since Srinivas took over the workshop from his father, he has been struggling to keep the original art form as new designs and trends keep coming up, following in the customer's change of mind.

But thankfully, his son is that one nascent modern addition to the craftsman’s family work, and now is an apprentice to his father.

Ms. Rashmi Pratap, editor of 30 states column, and an art and cultural enthusiast, held a conversation with the father-son duo about their craft, its legacy and their concerns.

Mr. Srinivas, now that we have a demand for kalamkari all round the world, we would like to know that was this the same case when your father started it?

My father had handlooms of fabrics. He used to produce fabrics and then take them to Chennai to explain to people about the craft, its beauty and its demand.

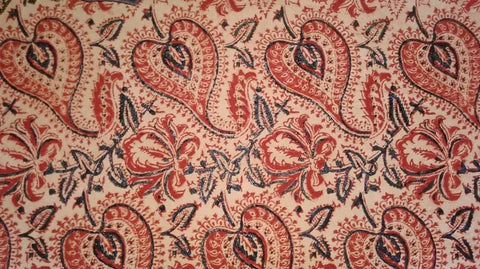

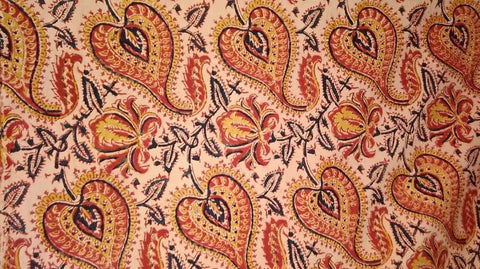

What is the most special thing about this craft that distinguishes it from other forms of kalamkari?

The fact that we still use our original traditional designs, slightly modified in modern touch, as floral motifs along with our famous old temple designs. Also, we use sustainable and biodegradable materials.

The father-son duo also told us about how they achieve their desired transient colours in their colour palette and how they are actually created. As per them its all about experimenting, in what can look good and what will look good. Keeping this in mind alum and water are mixed together in proportionate ratios in Meherban seeds powder.

How impact does the alkaline level of water have on the prints?

Usually we make use of the groundwater, and when printing is done we wash the fabric in the krishna river, as goat dung is used while printing so washing helps. The fabric is boiled into 100 degree to 110 degree water, in copper made boiling containers. Basically, everything depends on the material.

What should be the base cloth for the pedana kalamkari to spark brighter?

As far as the appeal of the fabric is, pedana kalamkari suits best over a cotton or a linen fabric. But definitely not silk, it is hard for the print to sustain over a silk fabric.

Varun tell us how you decided to join your father in your family business?

I was in my third year of college when one day I was returning from college and my eyes caught a glimpse of this beautiful fabric laid at our unit. I was very intrigued about it’s making from scratch and that it is a sustainable fabric. I wanted to delve into the process,hence, I decided to join my father after completing my engineering.

Do you work for the clerical Marketing/Sales department or have you learnt the craft?

I actually learnt the craft for 2 years after completing my graduation. So, now I actually create the designer blocks for the print.

The one thing every person is concerned about in daily life is the quality of life. Same goes for the quality of articles we use. Sustainability is a major vital part of our life these days. People have finally started to realise how important it is to preserve the environment. With reference to this we asked the Srinivas' about their take on this subject matter.

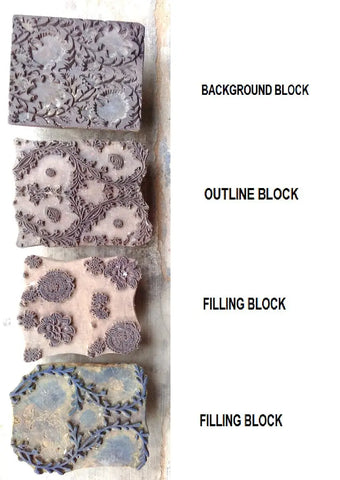

Which wood is required to make the blocks?

These blocks are made of teak wood so that they keep in shape for a long period of time. What happens is, if we use any other wood it turns into either a concave of a convex shape. So, to keep it aligned and intact we use teak wood.

Teak wood is considered to be one of the most durable woods and hence articles made from that wood have longevity and resilience. It is expensive but it entirely justifies it as it is valuable both for its elegance and its durability. Purchasing it makes us relieved for years just like the saying goes“mehnga roye ek baar, sasta roye baar baar”.

When it comes to the alluring Kalamkari prints, maximum of the credit goes in the creation of the blocks on which the designs are engraved. After their creation, the blocks are usually soaked in sesame oil for 3-4 days to prevent water from seeping in the block. The amount of cloth the block can print, usually depends on the length of the cloth. For instance, 20 meters of cloth can approximately be printed with one block varying upto 30 metres a day by one artisan. The block later on is cleaned with a soft brush. If in any case the block is damaged due to any reason, it is thereon archived in the Srinivas’ personal little block museum. They have all the ancient blocks there, some older than 20 years, and the ones the Srinivas’ have used and also the ones his father used 40 years ago.

It takes about 15 days for one order to get ready as Srinivas’ have 60 employed local artisans whom he trains initially and then they are bifurcated in his stitching, boiling, and printing unit respectively as per their expertise.

The product which requires more than one colour coating takes even longer as every coating requires 24 hours to dry out. Every piece of work is diligently crafted keeping the big name and goodwill in mind.

“Covid 19 did have an adverse effect on the creation of the craft, but not on the sales. All this was made possible by online sales, thanks to Itokri. Ever since I collaborated with them I am pretty satisfied with the Indian as well as foriegn market too, especially US market.”

Mr.Srinivas

Master Artisan

check original pedna kalamkari products by Pitchuka Srinivas, here.

Blogs you might also like:

Bandhani Tie & Dye

Painting with thread- The art of embroidery

Chopad - The oldest indigenous game of India

Verified Purchase

Verified Purchase

Sonali Mishra

Liquid error (sections/custom_blog_posts line 652): The format option 'month_day_year' is not a supported format.

Thank you so much for this. I’ve been very interested in kalamkari and especially Matchlipatam kalamkari. I’m a historian and my research is also around this. Besides, I’m in love with kalamkari textiles.